I wanted to go ahead and do part 2 of my Organization posts, but first, I am excited about something new we are selling on our website. I looked back through my old records, and on June 4, 2007 I purchased my first embroidery (font) software. If you’ve read my blog, you know I use Monogram Wizard Plus for my fonts (names & initials) and I use Sew What-Pro for merging and editing. I bought MWP first and have loved it for almost EIGHT years!! I don’t have to tell you I love SWP too, as we’ve been selling it on the website (here) for a little over a year now and I mention it on my blog quite often. It’s become our top seller each month over any single applique design. We are now selling Monogram Wizard Plus too, and while it’s more expensive than SWP, it’s worth every penny! I’ve used it for the past almost-8 years, so it calculates to just $30 a year thus far. It’s a great investment if you are in the business of embroidery and monogramming! Check it out – click HERE!

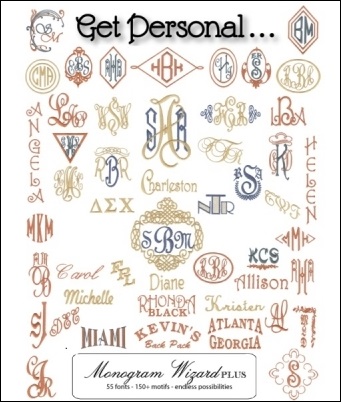

Here is just a sampling of what you can do in Monogram Wizard Plus. Lots of great fonts and motifs:

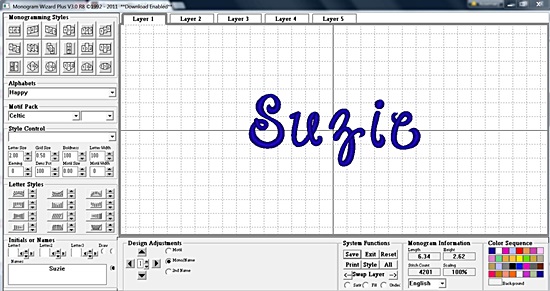

Here is a screen shot of your workspace in MWP. It’s super easy to use and super easy to scroll through all of the various font options, sizes, etc. Again, a great investment! You can click on the TAG Monogram Wizard Plus on the right column, or search “Monogram Wizard Plus” on my blog in the search box. There is also a post or two in Helpful Posts.

Now on to ORGANIZATION. As a follow up to my last post, Part 1, Kristi D. messaged me about a couple of apps you can download to help with to do lists and organization. They are: Evernote and Todoist (not “todolist”, but todo+ist). I just downloaded Todoist so I will try it out and see how it works! It looks like you can add tasks to certain days, set up reminders, etc. I just downloaded it so I haven’t gotten far yet! I may still be a pen and paper kind of girl but will give it a try!

OK…..

When is the best time to work?

I think everyone might answer this question differently because we are all in different stages of life and all have different schedules. Beth S. answered “I try to throw one or two things on the machine after my kids go to bed. I get a lot done when my husband takes my boys to practices.” (yay hubby!) Beth also works from home on Fridays so she tries to get 5 or more things on the machine on Fridays. For me, I try to get work done when my kids are at school. They go to a classical Christian school and they get out at 12:30 every day, so this is sometimes hard! Morning is my time to run my errands sans kids, go to bible study, volunteer at their school, etc. Usually 1 or 2 mornings a week I get to just stay home and work. I also try to work in the afternoons while they are doing their homework, but this is usually chaotic and I’m constantly interrupted and usually get frustrated. I try NOT to work much when Jeff gets home from work and throughout the evening, but sometimes it happens a day or two a week while the boys are at soccer practice. I also try to avoid working on the weekends unless we have NOTHING to do and I need to knock out a job or two. as I type this on Sunday afternoon…. If your kids are small and take naps, nap time is a great time to try to get a few things done! Maybe nights and weekend are your only time to work. That’s fine too! Just don’t sacrifice precious time with your family to work unless you have to.

Overall I think you have to look at your schedule and try to carve out time when you can get some work done uninterrupted! If you do this part time, you need to set hours and stick to them. I have a friend who lives in Atlanta who once told me that he intentionally gets up in the mornings, gets dressed and purposefully goes out for coffee or to grab breakfast. He then “goes to work” which is back at home. It’s hard to separate yourself from being at home when you work there! I am often distracted by laundry, cleaning, the dog, watching TV (I love The Today Show!), etc.

This is what happens when I try to work in the midst of kids!!

When is the best time to check email (other than every 5 minutes like I do sometimes….)?

I would add to this: Facebook, Pinterest, Instagram and all the other “distractions” I struggle with that are “for work” but can distract me for an hour!! When we first started Applique Cafe, I worked out of our dining room in our old house and felt the need to check email literally every time I walked by the dining room. It was out of control! Depending on what your business is and how important email is to you, I would say to check it 3 times a day. Set a schedule and try to stick to it barring special circumstances. Try to check it in the morning when you get up or sometime in the morning when you have a few minutes. Check it at lunchtime or in the afternoon if you are away from home during the day. Lastly, check it quickly at night before heading to bed. We do have to check ours often b/c the majority of our business is email, but I have found that if I check it too much, I am taking time out of my day to check it and may only receive 4 emails b/c I just checked it 20 minutes ago!

Social Media… if anyone is guilty of wasting too much time on social media, it is ME! There is no telling what I could accomplish in the hours and hours I’ve wasted since Facebook was invented! If you use social media for your business, try to stick with the same 3 or so times a day rule. Yes you might need to check Facebook to see if you have any messages or comments you need to check on. What you don’t need is to open Facebook in the middle of sewing a shirt and waste 30 minutes scrolling through to see what all your friends are up to! Same with Pinterest and Instagram! Both are great tools for business and most importantly they are FREE, but they can also distract you from your work and next thing you know an hour has passed and you haven’t even finished a single monogram! SET LIMITS!!

How many items do you do each day? Goals are good!!

Beth S. says that she sets small goals. If she has 11 baseball bags on her to do list, then she tries to complete 2 to 3 a day. If she finds some extra time here or there, she can usually exceed her goal. I agree with Beth in that small goals are a great idea! I not only do this with embroidery work, but I do it with my every day stuff as well. Every day I either think about what I need to get done that day or write it down. It might be: go to the bank, send out X email, bathe the dog, monogram Leslie’s 2 items. Doesn’t it feel good to mark those things off the list, 1 by 1? I might have 32 embroidery items on my to do list, but know today is sort of a busy day and I don’t have a lot of time. Set a small goal of monogramming 1 thing, or 2 or 3 things. A lot of times you might be able to squeeze in 1 more and that’s great, but if you can’t, then at the very least you can accomplish the small goals before the day is done!

That’s all for today! I will continue next time with time savers & tips for doing monograms and appliques and the easiest fastest way to pick out fabric and thread colors! I would love to read your comments or suggestions for ORGANIZATION, so comment away!

Recent Comments